Trucut Tools, Suisse Autoturn partner to introduce TaeguTec's new range

Published by Gary Priestley on 14th Apr 2025

Suisse Autoturn Ltd in Portsmouth (Hampshire UK), have vast experience and exceptional reputation in the Swiss Sliding Head machining market, their expertise has been honed over 40+ years. Involved in markets which range from Aerospace, Formula 1, Medical/Prosthetics, Electronics and Marine, with components being produced from Steel, Stainless Steel, Non-Ferrous and Exotic Alloys. Terry commented “Customers requirements dictate the range of tooling required, flexibility and versatility are requirements when looking at the ‘T’ Max depth, widths and consideration of the variety of materials, from which our components are produced”.

Over many years Swiss Sliding Head tooling has evolved, with accuracy of location being imperative, ease of use with a quick precise change being another prerequisite. Every Micron matter’s when the components being machined are to fine tolerances, the material itself can influence these tolerances. An example can be taken from ovality in Bar diameter, lengths of bar from which components are produced, are fed through and supported by the Sliding Head Guide Bush, any ovality will be replicated exactly in the finished components, hence the use of ground bar.

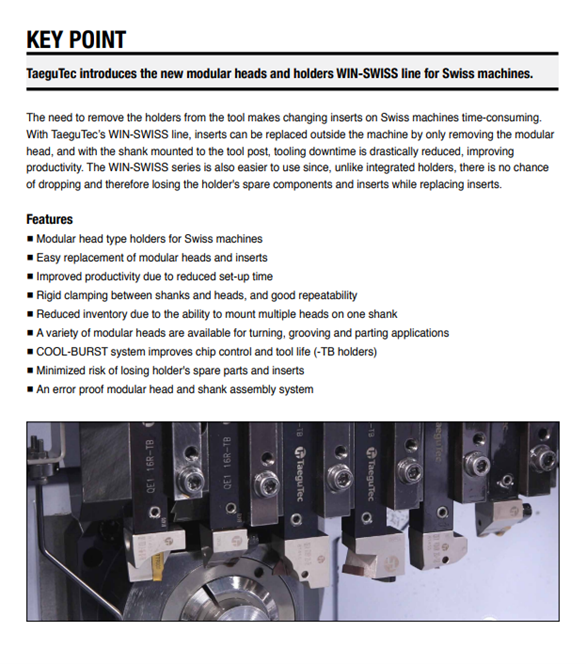

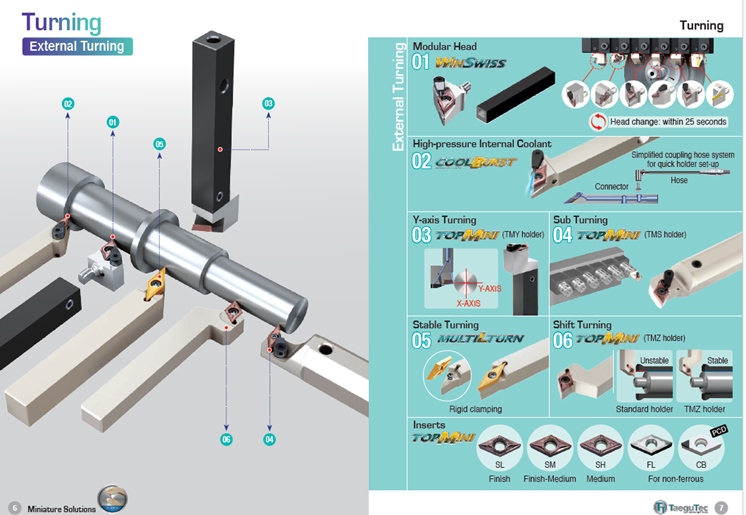

Enter the new WINSWISS system from tooling specialists TaeguTec, who have developed a comprehensive range of Modular Sliding Head tooling, focusing on improving existing tooling available to the market. Their objectives for the new WINSWISS range? To deliver a high-performance Swiss Sliding Head system, which minimise machine down time and maximise up time productivity through a greater choice of Insert Geometries, Grades utilized in a considerable range of extremely accurate quick change Modular Heads.

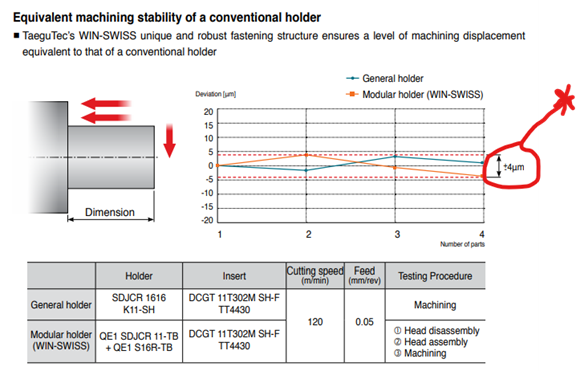

Rigidity of the WINSWISS system Vs Conventional Tooling as Below:

Not satisfied with their own understanding of this complex market, TaeguTec then pushed the boundaries further, involving Machinists and Sub-Contractors, incorporating suggestions to tooling designs around their ideas/production needs. Keen to be involved in this development, Trucut Tools set up a joint meeting with Suisse Autoturn Ltd Engineers and TaeguTec Tooling Design Engineers, seen as an opportunity to discuss and clarify, an accurate view of the market from a customer’s perspective, identifying where the voids in the Swiss Sliding Head Tooling Market were still evident.

TaeguTec have borne these voids in mind, identifying areas where accuracy and performance could be improved, developing their comprehensive range of Swiss tooling still further. New Insert chip formers, geometries and wiper facets to help cope with the day-to-day anomalies within material grades were paramount. Insert/Holder pocket seating security has been designed to provide an extremely rigid and secure location, leading to increased cutting-edge stability, as a result performance and tool-life consistency have increased dramatically.

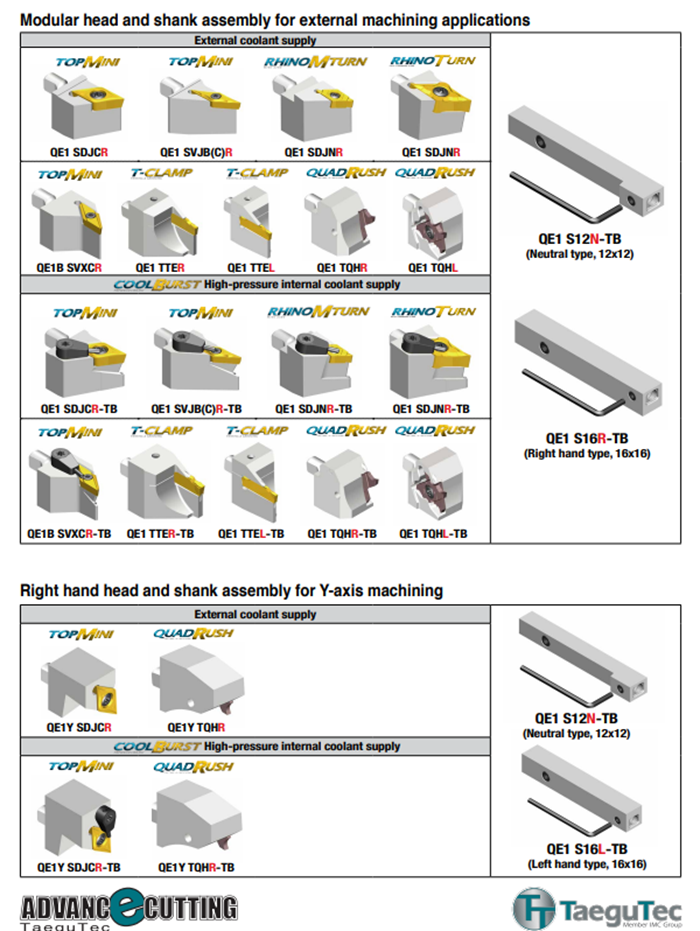

Basic Modular Shank Sizes are available as 12mm and 16mm square options, these accept both Right/|Left Hand modular heads, the Modular heads from both Sizes (12mm/16mm), fitting into either Basic Modular Shank size 12mm or 16mm. Location of each head is precise and stable, reducing downtime when changing. Product range development is still ongoing to make the system as complete as possible, TaeguTec are focusing their sights on production of a 10mm square modular system, both Trucut Tools and customers are looking forward to seeing this addition to the range.

See WINSWISS Sliding Head Tooling.

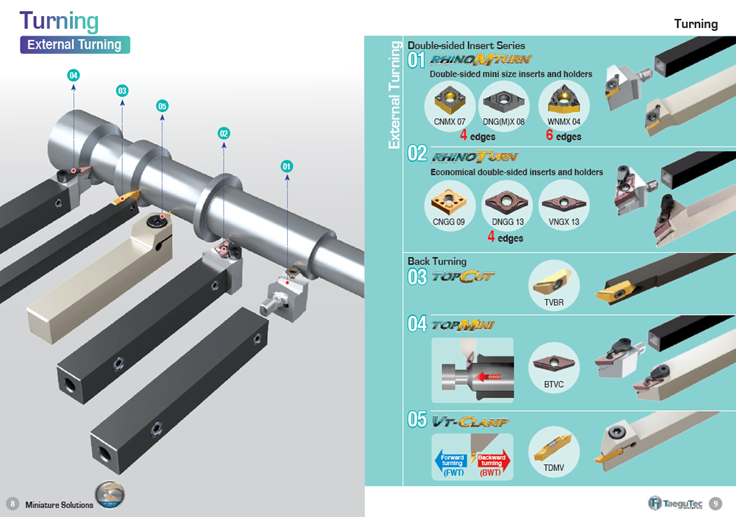

See the TaeguTec Miniature Solution Information.

Location: Suisse Autoturn Ltd

Title Description: Swiss Tooling Range where microns matter.

Presentation – TaeguTec Product Specialists UK & South Korean Engineers

Product Description: TaeguTec WINSWISS Sliding Head Tooling Presentation

Suisse Autoturn Ltd Engineers: Terry Fuggle (Owner), Nick Dawson (Machine-shop).

TaeguTec UK Ltd: Iain Lacayo (Technical Sales Engineer), Jae-Wook Jung (Miniature Product Manager), Jun-Seok Park (Design Engineer R&D Tools & Design Dept).

Trucut Tooling Ltd: Gary Priestley (Technical Sales Engineer).