Unlocking Machining Performance with the V Series End Mills

Published by Magda Quinn on 4th Sep 2024

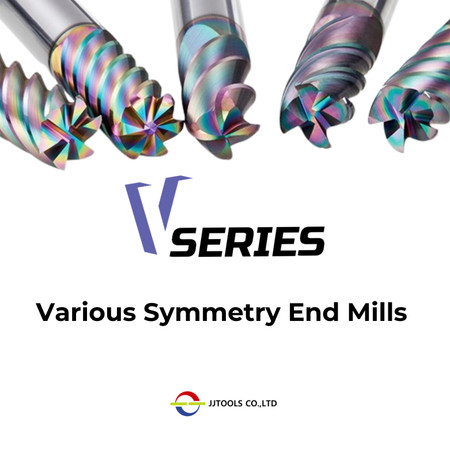

Unlocking Machining Performance with the V Series End Mills

Precision and efficiency are paramount in the demanding world of high-speed milling. The V Series from JJ Tools is a standout collection of Solid Carbide End Mills designed to meet the rigorous requirements of modern CNC machining. These High-Performance Cutting Tools are engineered with efficiency in mind, ensuring high performance across various industries, including aerospace, mould and die machining, and more.

Innovation at Its Core: Unequal Pitch Design

At the heart of the V Series is its unequal pitch design, a feature that sets these tools apart from the competition. This innovative design minimises noise and vibration—common challenges in high-speed milling—by varying the pitch of the bottom flute. The result is a smoother operation with reduced chatter, ensuring superior surface finishes and extended tool life. For those working in high-efficiency environments, these High-Efficiency Milling Tools are essential. The unequal pitch design enhances the tool's stability, leading to more precise and efficient milling.

Advanced Flute Design: Enhancing Tool Life

The V Series also boasts an improved flute design, featuring a shield edge that prevents the breakage of flute ends, a critical enhancement for intense milling tasks. This design ensures the tool's longevity and maintains consistent performance across a wide range of materials. Whether you're involved in aerospace or mould and die machining, these Precision Carbide Tools deliver the high performance and reliability needed.

Mastering Chip Evacuation: Multiple Helix and Wide Chip Pockets

Efficient chip evacuation is crucial for maintaining the integrity of both the tool and the workpiece. The V Series employs a multiple helix design with an unequal lead, optimising chip evacuation and allowing for faster cutting speeds. Paired with wide chip pockets, these tools ensure excellent swarf removal, keeping the cutting area clean and reducing the risk of re-cutting chips—a common cause of tool wear. These features make the V Series ideal for those seeking High-Efficiency Milling Tools.

HR Coating: A New Standard in Wear Resistance

The V Series tools by JJ Tools are known for their advanced coating technology, particularly the HR (High Resistance) coating. This coating combines Titanium Silicon Nitride (TISIN) with a chromium treatment and is designed to improve tool performance and longevity. It offers exceptional resistance to wear, reduces friction, and minimises heat transfer during machining. These properties ensure smoother cutting, efficient chip evacuation, and reduced thermal stress, making the V Series tools ideal for high-speed and precision machining applications. In addition to extending tool life, the HR coating enhances overall productivity and surface finish quality in demanding machining environments.

Tailored Solutions for Every Application

The V Series is designed to address specific milling challenges across various industries:

- 4VCC and 5VCC: These tools, featuring various symmetry corner chamfers, are ideal for tasks requiring enhanced corner radii.

- 4VSB and 4VSE: These versatile 4-flute end mills excel in machining a range of materials, making them High-Performance Cutting Tools for high-speed applications.

- 6VSE and 6VSC: With six flutes and various symmetry corner radii, these tools are perfect for applications demanding precise edge tolerance and minimal chipping, such as Carbide Tools for Mold & Die Machining.

- 7SUC: A 7-flute non-symmetry corner radius end mill designed for specialised operations requiring non-standard flute geometries.

- 5&6TROE: Trochoidal milling is a highly efficient machining method that maximises productivity through low radial depth of cut and high axial depth of cut, ideal for high-speed operations. The process employs a spiral toolpath, which expertly controls the radial contact area, ensuring consistent chip thickness throughout machining. This precise management of the tool’s engagement with the material is the hallmark of trochoidal milling, delivering superior performance and accuracy. The 5 TROE and 6 TROE End Mills are explicitly designed for trochoidal milling applications. These tools feature advanced geometries tailored to optimise the benefits of trochoidal milling.

Precision Machining for Tough Materials

The V Series doesn’t shy away from hard-to-cut materials like titanium. Its Titanium-Optimised Multi-Flute Design minimises edge damage and enhances cutting efficiency, which is crucial for maintaining tool life in demanding environments. Combined with advanced HR coating and anti-chatter design, these tools are a reliable choice for challenging applications.

Conclusion: The Future of Milling

The V Series from JJ Tools represents a significant advancement in milling technology. Whether you're working with high-speed operations, exotic materials, or precise edge finishes, these Solid Carbide End Mills provide solutions that exceed expectations. With its innovative design and specialised coatings, the V Series is poised to set a new standard in the industry.

For milling applications in aerospace, mould and die machining, or any other precision-focused industry, the V Series represents an investment in High-Efficiency Milling Tools that promise long-term returns in both performance and efficiency.